Description

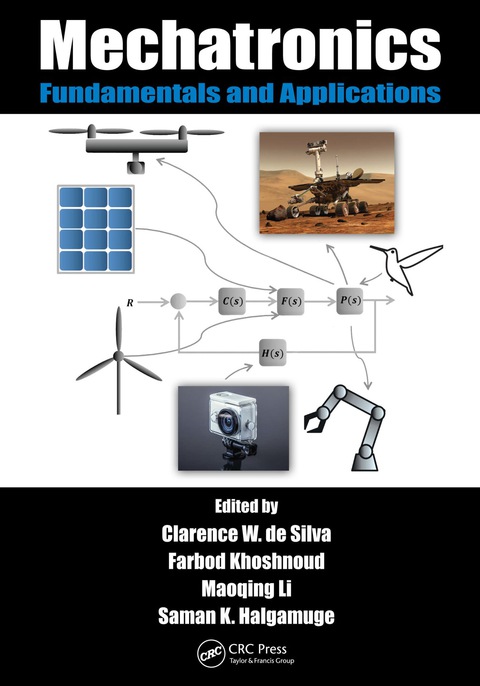

Efnisyfirlit

- Contents

- Preface

- Acknowledgments

- Editors

- Contributors

- Chapter 1: Mechatronic Engineering

- 1.1 Introduction

- 1.2 Modeling and Design

- 1.3 Mechatronic Design Concept

- 1.3.1 Coupled Design

- 1.3.2 Mechatronic Design Quotient (MDQ)

- 1.3.3 Design Evolution

- 1.4 Mechatronic Instrumentation

- 1.5 Evolution of Mechatronics

- 1.6 Application Areas

- 1.7 Conclusion

- References

- Section I: Fundamentals

- Chapter 2: Modeling for Control of Rigid Bodies in 3-D Space

- 2.1 Introduction

- 2.2 Theory

- 2.2.1 Definitions and Assumptions

- 2.2.2 Equations of Motion for the Linear Model

- 2.2.3 Linear Momentum Force Systems

- 2.2.4 Generalization of the Equations of Moment of Momentum

- 2.2.5 Assembly of Equations

- 2.3 Modeling Sensors and Actuators into the Model

- 2.3.1 Modeling Actuators

- 2.3.2 Modeling Sensors and Feedback

- 2.4 Introduction to Software MBDS

- 2.4.1 A Simple Two-Mass Spring System with an Actuator and a Relative Velocity Sensor

- 2.4.2 Response of the System to a Simple Step Function

- 2.5 Conclusions

- References

- Chapter 3: Mechanics of Materials

- 3.1 Elastic Stress and Strain

- 3.1.1 Introduction

- 3.1.2 Load

- 3.1.3 Stress

- 3.1.4 Nonuniform Stress

- 3.1.5 Complementary Shear Stresses

- 3.1.6 Deformation

- 3.1.7 Strain

- 3.1.8 Elasticity and Yield

- 3.1.9 Hooke’s Law and Elastic Constants

- 3.2 Theory of Bending

- 3.2.1 Introduction

- 3.2.2 Definition

- 3.2.3 Sign Convention of Bending Moment and Shearing Force

- 3.2.4 Bending Moment and Shear Force Diagrams

- 3.2.5 Bending Stresses

- 3.3 Deflection of Transverse Loaded Slender Beams

- 3.3.1 Beam Deflection

- 3.3.2 Flexure Equation

- 3.3.3 Equilibrium and Determinacy

- 3.3.4 Bending Moments

- 3.3.5 Flexure Equation

- 3.3.6 Deflection of a Transverse Loaded Beam

- 3.3.7 Deflection of Statically Indeterminate Beams

- 3.3.8 Beams with Discontinuous Bending Moment Equations

- 3.3.9 Singularity Function Method (Often Called Macaulay’s Method)

- 3.4 Theory of Torsion

- 3.4.1 Introduction

- 3.4.2 Shear Strain/Stress Distribution

- 3.4.3 Torque T and Rate of Twist

- 3.4.4 Shear Stress from Torsion

- 3.5 Stress Transformation in Two Dimensions

- 3.5.1 Introduction

- 3.5.2 General State of Stress in Three Dimensions

- 3.5.3 General State of Stress in Two Dimensions

- 3.5.4 Analysis of Plane Stress in Two Dimensions

- 3.5.5 Calculation of Strains from Stresses

- 3.6 Strain Analysis and the Strain Gauge Rosettes

- 3.6.1 Introduction

- 3.6.2 Strain Gauge Rosettes

- 3.6.3 Conversion from Principal Strains to Principal Stresses

- 3.7 Mechanical Properties of Materials

- 3.7.1 Introduction

- 3.7.2 Tension and Compression Tests

- 3.7.3 Stress–Strain Behavior of Ductile Materials

- 3.7.4 Poisson’s Ratio

- 3.8 Conclusions

- References

- Chapter 4: Control of Mechatronic Systems

- 4.1 What Is a Mechatronic System?

- 4.2 Overview of Control Systems

- 4.2.1 System Model

- 4.2.2 System Modeling Applied to Components of Mechatronic Systems

- 4.2.3 Performance Assessment of a Control System

- 4.3 Control Techniques

- 4.3.1 Feedback Proportional–Integral–Derivative (PID) Control

- 4.3.2 Feedforward Control

- 4.3.3 Servo Control Structures

- 4.3.4 Programmable Logic Controllers

- 4.4 Implementation of a Computer Control

- 4.5 Challenges in Control of Mechatronic Systems

- 4.5.1 Friction

- 4.5.2 Force Ripples

- 4.5.3 Hysteresis and Backlash

- 4.5.4 Saturation

- 4.5.5 Dead Zone

- 4.5.6 Reference Signal Changes

- 4.5.7 Low-Frequency Drift

- 4.5.8 High-Frequency Noise

- 4.5.9 Incorporating and Addressing Nonlinear Dynamics

- 4.6 Application Examples

- 4.6.1 Flight Simulators

- 4.6.2 Piezoelectric Control System for Biomedical Application

- 4.7 Conclusions

- Bibliography

- Chapter 5: Introduction to Sensors and Signal Processing

- 5.1 Introduction

- 5.2 Signals

- 5.2.1 Types of Time Signals and Waveforms

- 5.2.2 Harmonic Signals

- 5.2.3 Quantification of Energy in a Signal: RMS

- 5.2.4 Useful Relationships and Common Waveforms

- 5.3 Fourier Analysis

- 5.3.1 Introduction

- 5.3.2 Fourier Transform

- 5.3.3 Fourier Transform Application Example

- 5.3.4 Basics of the Discrete and Fast Fourier Transforms

- 5.4 Signal Processing

- 5.4.1 Aliasing

- 5.4.2 Quantization Errors

- 5.4.3 Leakage and Windowing

- 5.4.4 Convolution

- 5.4.5 Random Signals

- 5.4.6 Butterworth Filter

- 5.4.7 Smoothing Filters

- 5.5 Sensors

- 5.5.1 Accelerometers

- 5.5.2 Velocity Transducers

- 5.5.3 Displacement Transducers

- 5.5.4 Strain Gauges

- 5.5.5 Load Cells

- 5.5.6 Temperature Sensors

- 5.5.7 Flow Sensors

- 5.5.8 Pressure Transducers

- 5.5.9 Ultrasonic Sensors

- 5.5.10 Other Sensors

- 5.6 Logarithmic Scales

- 5.6.1 Decibel

- 5.6.2 Octave

- 5.7 Conclusions

- References

- Chapter 6: Bio-MEMS Sensors and Actuators

- 6.1 Introduction

- 6.2 Bio-MEMS Actuators

- 6.2.1 Artificial Muscles

- 6.2.2 Ciliary Actuators

- 6.2.3 Nanotweezers for Micromanipulation of Biomolecules

- 6.2.4 Application of Capillary Valves in Microfluidic Devices

- 6.2.5 Drug Delivery

- 6.2.6 Biomolecular Systems

- 6.3 Bio-MEMS Sensors

- 6.3.1 Triglyceride Biosensor

- 6.3.2 Bio-MEMS Sensor for C-Reactive Protein Detection

- 6.3.3 Glucose Detection

- 6.3.4 MEMS Force Sensor for Protein Delivery

- 6.3.5 Tissue Softness Characterization

- 6.3.6 Blood Cell Counter

- 6.3.7 Acoustic Sensor

- 6.4 Conclusions

- References

- Chapter 7: System Identification in Human Adaptive Mechatronics

- 7.1 From Manual Control to Human Adaptive Mechatronics

- 7.2 Human in the Loop

- 7.3 Classical HO Model

- 7.3.1 Quasi-Linear Structure

- 7.3.2 Crossover Model

- 7.4 Identification of Quasi-Linear Model

- 7.4.1 Signal and Spectra

- 7.4.2 Nonparametric Quasi-Linear Model

- 7.4.3 Parametric Quasi-Linear Model

- 7.4.4 Experiment and Model Identification Results

- 7.5 Identification through Optimal Control Theory

- 7.5.1 Linear Regulator Problem

- 7.5.2 LQG Controller without Time Delay

- 7.5.3 LQG Controller with Time Delay

- 7.5.4 Optimal Control Model for the Human Operator

- 7.5.5 Human Optimal Control Model (OCM)

- 7.5.6 Motor Noise Effect

- 7.5.7 Modified Optimal Control Model (MOCM)

- 7.5.8 Identification of Optimal Control Model

- 7.5.9 Data-Based HO Model Identification

- 7.6 Conclusions

- References

- Chapter 8: Intelligent Robotic Systems

- 8.1 Introduction

- 8.2 Biological Immune System

- 8.2.1 Jerne’s Idiotypic Network Theory

- 8.3 Artificial Immune System (AIS)

- 8.3.1 Network Theory Model

- 8.4 Multi-Robot Cooperation Problem

- 8.4.1 Fault Tolerance

- 8.4.2 Decision Conflicts

- 8.4.3 Interdependencies and Priorities

- 8.5 Multi-Robot Cooperation and Artificial Immune System

- 8.5.1 Binding Affinity

- 8.5.2 Robot and Antibody

- 8.5.3 Multi-Robot Cooperation and Modified Idiotypic Network Model

- 8.6 Genetic Algorithm

- 8.6.1 Operators of GA

- 8.6.2 Simple GA

- 8.7 Optimizing Binding Affinity Function Using GA

- 8.8 Results and Discussion

- 8.9 Conclusions

- References

- Section II: Applications

- Chapter 9: Automated Mechatronic Design Tool

- 9.1 Introduction

- 9.1.1 Mechatronic Design Theory

- 9.2 Evolutionary Mechatronic Tool

- 9.2.1 Genetic Programming

- 9.2.2 Bond Graphs

- 9.2.3 Integration of Bond Graphs and Genetic Programming

- 9.3 Controller Design Using Bond Graphs

- 9.4 Two-Loop Design Model

- 9.4.1 Hybrid Genetic Algorithm with Genetic Programming

- 9.4.2 Case Study: Iron Butcher Controller Design [15]

- 9.5 Niching Optimization Scheme

- 9.5.1 Niching Genetic Programming

- 9.5.2 Case Study: Model-Referenced Active Car Suspension [19]

- 9.5.3 Case Study: Hydraulic Engine Mount Design

- 9.6 Conclusions

- References

- Chapter 10: Design Evolution of Mechatronic Systems

- 10.1 Introduction

- 10.2 Modeling Multidomain Systems

- 10.2.1 Bond Graph Modeling

- 10.2.2 Linear Graphs

- 10.3 Design Evolution

- 10.3.1 Evolutionary Design Framework with BGs

- 10.3.2 Methodology

- 10.3.3 Solution Representation for the Evolution

- 10.3.4 Fitness Function

- 10.4 Application of Methodology to Industrial Systems

- 10.4.1 Illustrative Scenario 1

- 10.4.2 Illustrative Example of Application of LG Methodology

- 10.4.3 Illustrative Scenario 2

- 10.5 Conclusions

- References

- Chapter 11: Mechatronic Design of Unmanned Aircraft Systems

- 11.1 Introduction

- 11.2 Unmanned System Hardware

- 11.2.1 Sensors and Measurement Systems

- 11.2.2 Computers

- 11.2.3 Actuator Management

- 11.2.4 Communication Unit

- 11.2.5 Hardware Integration

- 11.3 Unmanned System Software

- 11.3.1 Onboard Real-Time Software System

- 11.3.2 Ground Control Software System

- 11.4 Case I: Design of a Coaxial Rotorcraft System

- 11.4.1 Hardware System

- 11.4.2 Software System

- 11.4.3 Experimental Results

- 11.5 Case II: Design of a UAV Cargo Transportation System

- 11.5.1 Hardware System

- 11.5.2 Software System

- 11.5.3 Experimental Results

- 11.6 Conclusion

- References

- Chapter 12: Self-Powered and Bio-Inspired Dynamic Systems

- 12.1 Introduction

- 12.2 Energy Harvesting

- 12.2.1 Energy Conversion Mechanisms

- 12.3 Self-Powered Dynamic Systems

- 12.3.1 Concept of Self-Powered Dynamic Systems

- 12.3.2 Theory of Self-Powered Systems

- 12.3.3 Renewable Energy for Dynamic Systems

- 12.3.4 Human-Powered Systems

- 12.4 Bio-Inspired Dynamic Systems

- 12.4.1 Piezoelecteric Energy Harvesting from Aeroelastic Vibrations

- 12.4.2 Fish Schooling Inspired Vertical Axis Wind Turbine Farm

- 12.4.3 Bio-Inspired Self-Propelled Vehicle

- 12.4.4 Bio-Inspired Flapping Wing Flying Robots

- 12.4.5 Bio-Inspired Flight Control System

- 12.4.6 Uncertainty Quantification

- 12.5 Conclusions

- References

- Chapter 13: Visual Servo Systems for Mobile Robots

- 13.1 Introduction

- 13.2 Mobile Robotic Visual Servo Systems

- 13.2.1 State of the Art of Mobile Robotic Systems

- 13.2.2 Typical Sensors

- 13.3 Visual Servoing

- 13.3.1 Basic Categories of Visual Servoing

- 13.3.2 Modeling of Visual Servo System

- 13.4 Case Study of Visual Servoing

- 13.4.1 System Modeling

- 13.4.2 Traditional Image-Based Visual Servoing

- 13.4.3 Adaptive Nonlinear Model Predictive Control

- 13.5 Conclusions

- References

- Chapter 14: Robotic Learning and Applications

- 14.1 Introduction

- 14.2 Markov Decision Process (MDP) and Q Learning

- 14.3 Case Study: Multi-Robot Transportation Using Machine Learning

- 14.3.1 Multi-Agent Infrastructure

- 14.3.2 Cooperation Based on Machine Learning

- 14.3.3 Simulation Results

- 14.3.4 Experimentation

- 14.4 Case Study: A Hybrid Visual Servo Controller Using Q Learning

- 14.4.1 Vision-Based Mobile Robot Motion Control

- 14.4.2 Hybrid Controller for Robust Visual Servoing

- 14.4.3 Experimental Results

- 14.5 Conclusions

- References

- Chapter 15: Neuromechatronics with In Vitro Microelectrode Arrays

- 15.1 Introduction

- 15.1.1 Evolution of Mechatronics

- 15.1.2 Neuromechatronics

- 15.1.3 Neuronal Networks

- 15.2 In Vitro Microelectrode Arrays (MEAs)

- 15.2.1 MEAs among Other Neural Recording Techniques

- 15.2.2 Functionality of MEAs

- 15.2.3 Strengths and Weaknesses of MEAs

- 15.2.4 MEA Systems and Software

- 15.3 Dynamics of Microelectrode Array Recordings

- 15.3.1 Spikes

- 15.3.2 Bursts

- 15.3.3 Network Bursts

- 15.4 Detection of Network Dynamics

- 15.4.1 Spike Detection

- 15.4.2 Spike Sorting

- 15.4.3 Burst Detection

- 15.4.4 Network Burst Detection

- 15.4.5 General Analysis Methods

- 15.4.6 Identifying Functional Motifs

- 15.5 Embodied Neural Networks

- 15.5.1 Supervised Learning

- 15.5.2 Unsupervised Learning

- 15.6 Conclusion

- References

- Back Cover